Application method of fmg-2.2 electric rail grinder

1、 Structure and working principle

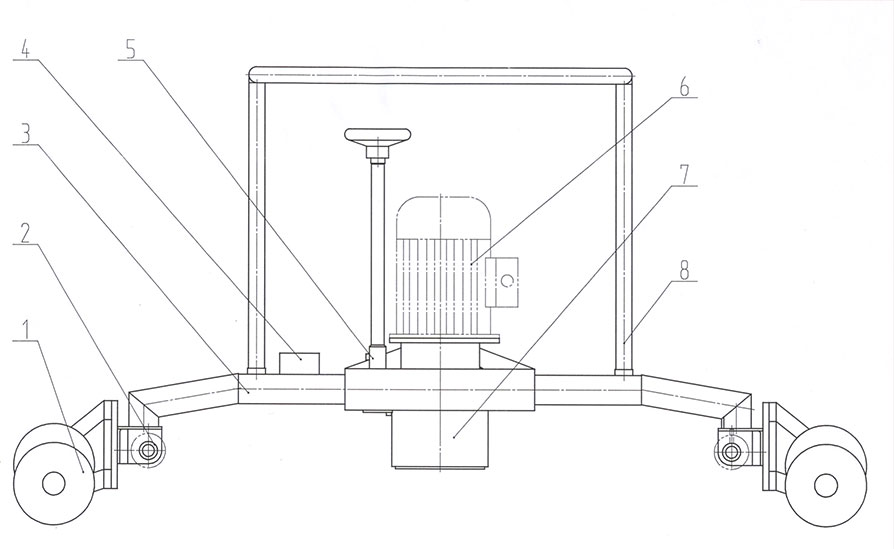

The machine is mainly composed of frame, guard wheel, profiling wheel, motor, grinding head, feed rod assembly, control handrail, etc. As shown in the figure:

1. Guard wheel 2. Profiling wheel 3. Frame 4. Switch

5. Feed assembly 6. Motor 7. Motor drive assembly 8. Operating handrail

During operation, the motor output shaft drives the grinding wheel installed on the grinding wheel adapter to rotate through the spline shaft and spline sleeve. The spline sleeve is installed in the feed sleeve through the bearing. The feed sleeve is a rectangular thread sleeve, which can slide up and down along the sleeve on the frame. The feed hand wheel engages a large gear through the feed pinion of the feed assembly. The large gear is an internal rectangular threaded part. The rotation of the large gear drives the feed sleeve to move up and down, so as to realize the feed movement of the grinding wheel. Operate the handrail to push the grinder to move longitudinally on the rail tread to grind the rail tread. Turn the frame at a considerable angle to grind the rail head circle angle until it rotates 90 °, and the grinding head grinds the rail working edge. During grinding, adjust the feed hand wheel of the grinding head, adjust the feed rate, and use the profiling wheel and guard wheel to complete the profiling grinding of the rail head.

2、 Method of use

1. Operation preparation

1.1 before operation, the operator shall be familiar with the structure, technical performance, working principle, use method and safety rules of the machine according to the instructions and requirements;

1.2 body preparation: Fasteners shall be fastened, moving parts shall be flexible, and electrical system insulation protection shall be reliable. Special attention shall be paid to the firm and reliable grounding of motor grounding wire;

1.3 test run: jog the electrical switch to check the rotation of the grinding wheel. If the rotation does not meet the mark, adjust the motor wiring to make the motor rotate forward, and confirm that the protection of the grinding wheel protective cover is effective;

1.4 no load running: run for 2 minutes without load, check whether there is any abnormality in all parts of the machine body, especially after replacing a new grinding wheel;

2. Grinding operation

2.1 place the grinder on the steel rail to be polished, and the power plug and power socket shall be in firm contact;

2.2 jog the switch and turn the feed handle counterclockwise so that the grinding wheel does not contact the top surface of the rail to be polished;

2.3 press the power switch and the grinding wheel rotates without load;

2.4 rotate the vertical feed handle clockwise evenly to make the grinding wheel move towards the rail top surface until it contacts the rail top surface to be polished and sparks are generated. At the same time, pull the handle to make the machine move back and forth from left to right when the profiling wheel is close to the rail top surface, with a range of about 800mm

2.5 evenly control the feed rate of grinding wheel, generally within 0.2mm each time, and check whether there are abnormalities and the thickness of grinding marks. The polished rail surface shall not show blue or obvious scratches;

2.6 when turning the handle, make the machine body incline gradually to the inner side along the cross section of the rail, expand the transverse grinding range of the rail top by virtue of the control of the guard wheel of the grinder, and grind from the center line of the rail top to the arc of the rail head;

2.7 slowly tilt the operating handrail to the operator, turn the grinder 90 ° inward along the cross section of the rail, and lift the grinder to grind the inner surface of the rail back and forth (working edge);

2.8 after the operation is completed, turn the feed handle in the opposite direction to make the grinding wheel back out of contact with the rail, press the power-off switch, and the grinding machine stops rotating. After resetting the grinding surface, lift the grinding machine, rotate it horizontally for 180 °, place it on the rail, and repeat the above actions, that is, the remaining part of the rail top surface and the outer side of the rail head can be polished, Until the grinding reaches the specified standard.