The working principle of Shenyang tamping machine is that the motive power generated by the engine is transmitted from the passive disk to the reduction gearbox. After the gear is decelerated, the rotation of the crankshaft gear drives the connecting rod, air piston and air piston up and down to impact the pickaxe drill tail, and the pickaxe drill carries out high-frequency and high-energy impact on the object, so as to realize the tamping of the working object.

Tamping machine can be divided into hydraulic tamping machine, flexible shaft tamping machine, internal combustion tamping pick and electric tamping pick.

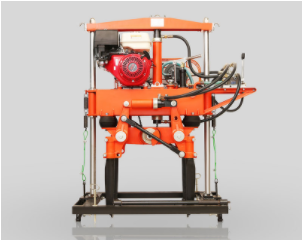

Hydraulic tamping machine:

The hydraulic tamping machine has double guide column frame structure and single cylinder lifting mode. Driven by diesel engine or motor; It is composed of gear pump, manual pump, directional valve, vibrating plate, tamping pick, lifting cylinder and clamping cylinder. Its working performance can fully meet the needs of line maintenance, and is also applicable to the tamping operation of new lines and the tamping operation after screening.

Internal combustion flexible shaft tamping machine:

The tamping machine is a new hand-held ballast tamping machine for railway track bed. The utility model is characterized in that the small internal combustion engine is directly connected with the tamping rod through the damping device, the structure is novel and practical, the volume is small, the weight is light, and the upper and lower tracks are very convenient. It is especially suitable for the maintenance and tamping of the speed-up line using the train gap.

Internal combustion tamping pick:

A small road maintenance machine suitable for railway track bed maintenance, which is mainly used for tamping ballast track bed. The utility model has the advantages of novel design and compact structure. It is a tamping equipment with fast up and down track and light operation, which is especially suitable for turnout tamping operation. The machine is mainly composed of gasoline engine, damping device, transmission shaft, vibrator and handle to form an independent and complete hand-held tamping machine. There is neither lengthy cable nor bulky flexible shaft. The structure is reasonable and compact and easy to use.

Electric tamping machine:

It is composed of control device, vibration damping device, vibration source and pick plate. The vibration motor shell is made of aluminum alloy precision casting with good heat dissipation. The handle and the vibration source are connected by elastic rubber, and the angle can be adjusted by Sector splint. Its working performance can fully meet the tamping operation of the line and the tamping operation after screening.