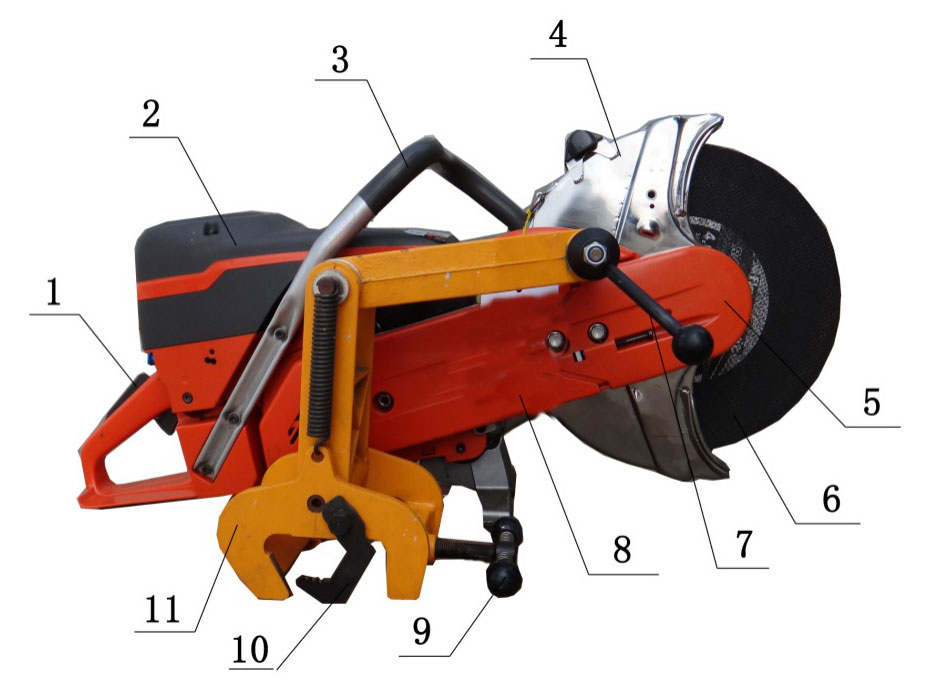

Structure and application method of nqg-5.8 internal combustion rail cutting machine

Main structure

The machine is composed of switch 1, engine 2, handrail 3, grinding wheel cover 4, grinding wheel blade 5, grinding head assembly 6, handle 7, belt cover 8, jacking wire 9, anti decoupling 10, rail clamp 11, etc.

usage method

1. Operation of mixed fuel

1.1 the two-stroke gasoline engine uses the mixture of 93 and above gasoline and special engine oil for two-stroke gasoline engine as fuel. The mixing ratio of gasoline and engine oil shall be 25:1 by volume. After mixing and shaking, it shall be added to the fuel tank. Pure gasoline shall not be used as fuel.

1.2 in the process of mixing fuel and refueling the machine, keep away from the fire source, do not smoke, and carry out it in an outdoor ventilated place.

1.3 refuel the machine after the gasoline engine stops running and cools down. When adding fuel, if gasoline overflows or falls outside the fuel tank, wipe it dry before starting the gasoline engine.

1.4 high temperature or blocked vent hole of the oil tank will volatilize the gasoline in the oil tank and form air pressure. In order to reduce the oil and gas pressure, carefully unscrew the oil tank cover and slowly release the pressure, but do not remove the gasoline cover when the machine is running.

1.5 clean the oil tank frequently. Before refueling, clean the filter screen in the oil tank cover and the surrounding dust to avoid dust falling into the oil tank.

2. Operation of gasoline engine

2.1 cold start

(1) Turn the shutdown switch to the left start position and pull out the choke.

(2) Press the activation pressure reducing valve on the right side of the machine. After the engine works, the pressure reducing valve will automatically bounce back to the normal position by the combustion pressure in the cylinder.

(3) Pull the throttle up and press the throttle lock lever.

(4) Hold the front handle firmly with your left hand, and step on the rear handle with your right foot close to the ground.

(5) Pull the start handle with your right hand to move slowly until you feel resistance, and then pull hard. When the gasoline engine is about to start, the start pressure reducing valve will pop up. Press again, press the start damper, and quickly pull the start rope, and the gasoline engine will start.

2.2 the steps of hot start and cold start are the same, but it is not necessary to pull out the starting damper.

2.3 after starting, push the choke and close the throttle to Z. at this time, the machine should run at idle speed.

3. Use of connecting frame

3.1 the lower end of the connecting arm is hinged with the rail clamping device with an articulated shaft and bolts, and the upper connecting shaft can be connected with the main machine of the rail cutter.

3.2 the rail clamping device can clamp 43 ~ 75kg / M rails of various models.

4. Installation of grinding wheel

4.1 confirm that the machine has not been started before installing the grinding wheel.

4.2 the hole diameter of the grinding wheel blade shall be consistent with the diameter of the grinding wheel shaft.

4.3 install the selected qualified grinding wheel (the linear speed must meet the requirements) on the main shaft.

4.4 install the grinding wheel pressing plate on the main shaft, and then tighten the left screw. The tightening torque is about 30 N.M.

4. Rail cutting operation

4.1 before each rail cutting operation, the machine must idle for 1 minute in advance before rail cutting operation.

4.2 the indicator pin of the device shall be aligned with the position to be cut, the bottom surface of the rail clamp shall be close to the upper surface of the rail, tighten the handle of the rail clamp device, and clamp and fix the rail clamp device on the rail.

4.3 align the mounting hole of the host with the connecting shaft of the connecting frame, insert it, and tighten the handle to make the host firmly fixed on the upper connecting frame.

(3) Start the gasoline engine. After the idle speed is stable, increase the throttle and lock the gasoline engine at z high speed. After the gasoline engine idles at z high speed for a few seconds, the grinding wheel gently contacts the rail head. If the grinding wheel deflects or jumps, replace the grinding wheel;

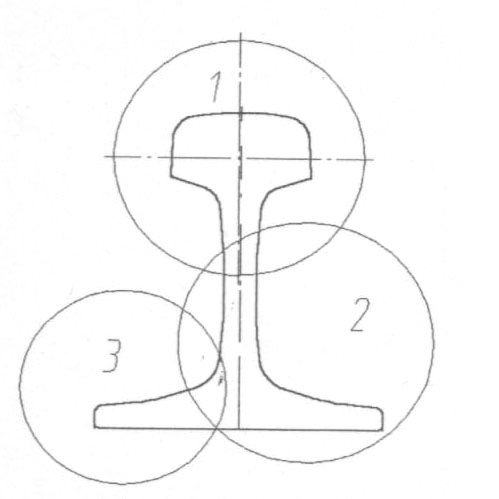

(4) First cut from the rail head position 1 to the rail waist, and then cut to the rail bottom position 2. When the grinding wheel is cut to the rail bottom on the other side, turn the rail cutter head to the other side, and cut down the rail bottom position 3 on the other side along the cutting seam until it is cut. If the saw blade does not move or is clamped during cutting, slightly change the cutting position and increase the swing range of the saw blade.

(Note: during rail cutting, the force is uniform and the grinding wheel is swung back and forth)

5. End job

After the operation, release the throttle trigger first, and then pull the stop switch to the position "stop" when the speed drops to Z low after a few seconds, and the gasoline engine will shut down. Loosen the head locking handle and remove the rail cutter host; Lift the anti falling hook, loosen the handle of the rail clamping device and remove the rail clamping device.

Note: put down the anti falling hook before rail cutting to prevent the rail clamping device of the rail cutting machine from falling off and hurting people; In the process of rail cutting, no one is allowed to stand in front and behind the rail cutting, so as to avoid personal injury caused by broken grinding wheel. No oil source or oil sprinkling is allowed near the cutting site to avoid fire.