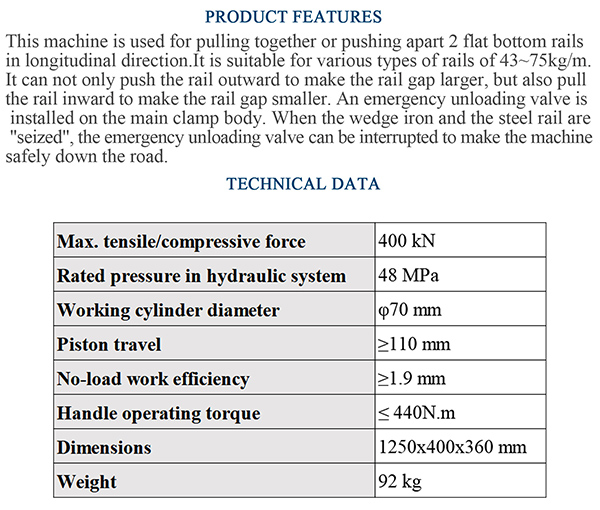

Closure weld under neutral temperature using a Hydraulic Rail Pulling And Pushing Device

When the required closure welds are made in continuously welded tracks, tension must sometimes be applied in order to ensure the optimum position. The rails must be placed in the correct longitudinal position before welding, in order to ensure the necessary distance from the rail ends. The hydraulic rail tensioning device is ideal for clamping, pressing and holding the rails in neutral length during the welding process. The profile free design also enables trains to run over it in the installed condition.

The advantages of this option are:

clamping yoke fitted on slab track and also over the rails

70 t tractive effort

profile free installation