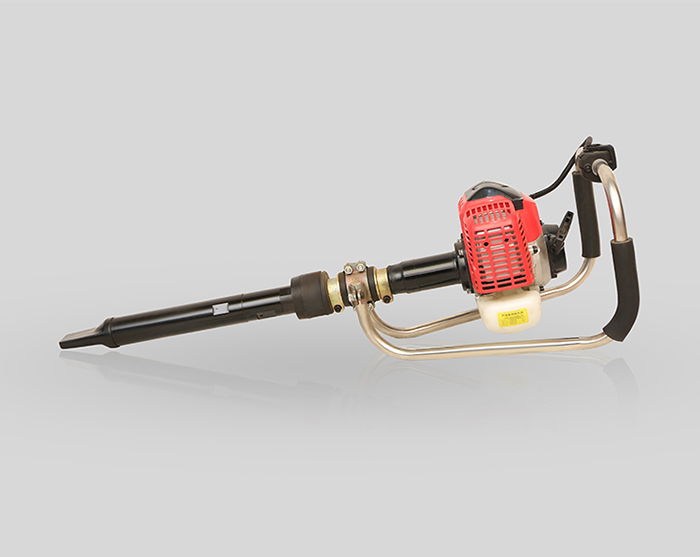

Fields of application are primarily areas in which no mechanical tamping is possible for economic or technical reasons. There are currently hand-held tampers with petrol engines or with electric drives on the market. The electrical devices have the advantage that the power source (motor or generator) is not directly attached to the device, however, there must be cable connections to the power source (risk of accident and obstacle). Hand tampers can, in principle, be divided into impact tampers and vibratory tampers. This older method of sleeper tamping copies the process of hand tamping used in the pre-mechanical tamping with the tamping pick (tamping pickaxe). The first development consisted in an extension of the sledge hammer used for demolition work. The effect of these impact hammers is rather modest due to the conditions under which they are used. Basically, only one piece of ballast can be moved at a time and the ballast stones will be damaged and crushed by the striking movement of the ram. Also damage to the lower edges of the sleeper cannot be ruled out. Due to the point application, the ballast bed does not oscillate in the place where the impact tamper is used. This results in a rather lo