Usage of yft-400 safety hydraulic rail gap adjuster

usage method

1. Before operation, the operator shall be familiar with the name, structure, performance and function of each part of the machine, precautions and operation methods of safety devices according to the requirements of the technical operation manual.

2. Open the oil filler cap (white nylon cap) above the oil tank and inject mechanical oil (No. 20 mechanical oil in summer and No. 10 oil in winter).

3. Carry out no-load test (open the oil return valve, shake the hand pump handle), remove the air in the system, check whether each part of the machine is flexible and whether there is oil leakage at each seal. After checking and confirming that it is normal, restore the machine to its original state.

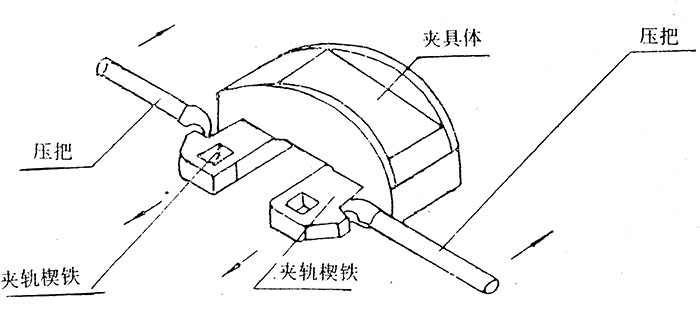

4. During operation, place the machines and tools on the top of the rail so that the rail clamping wedge is located on both sides of the rail, close the oil return valve and press down the lifting handle. At this time, the running wheel will automatically separate from the rail surface, and the rail clamping wedge will clamp the rail.

5. Insert the handle rod into the handle sleeve above the oil tank and press the plunger pump up and down to reduce the hydraulic oil pressure

Enter the cylinder and force the plunger of the hydraulic cylinder to extend. With the increase of pressure, the cylinder plunger and clamp extend to push the rail to adjust the rail gap.

6. After the operation is completed, open the oil return valve (rotate about 180 degrees to the left) to unload, and the oil cylinder plunger will automatically reset under the action of spring. Then lift the handle upward, and the rail clamping wedge and running wheel can automatically return to the original position. At this time, the machine can be pushed to the next working point on the rail.

Precautions and operation method of safety device

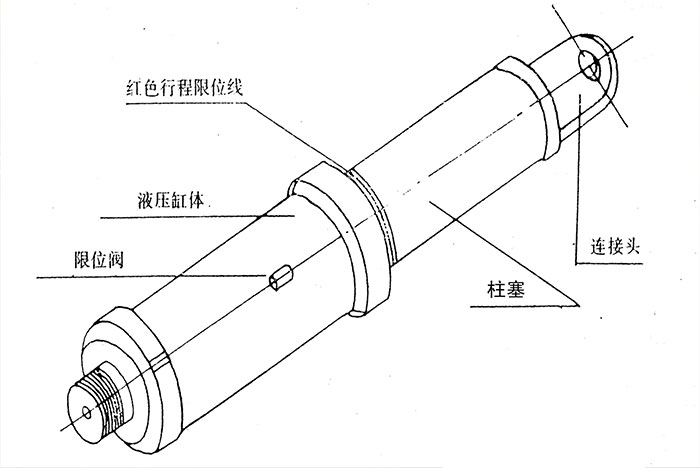

1. The extension of oil cylinder plunger shall not exceed 110mm. When the extension exceeds 110mm, you can see the red stroke limit line set on the plunger of the oil cylinder. If you continue to work, the limit valve will open automatically. At this time, open the oil return valve immediately (see the general drawing) to reset the oil cylinder automatically.

2. The safety valve (inside the oil tank and under the white nylon cover) has been debugged before leaving the factory. Generally, it shall not be adjusted at will.

3. If the oil return valve is opened (rotated about 180 degrees to the left) and the rail clamping wedge is found stuck on the rail, the oil cylinder cannot be reset. Use one of the following two methods to automatically release the wedge iron and reset the oil cylinder.

(1) Remove the dial on the press handle and pry the wedge iron between the rail clamping wedges on both sides of any head of the machine at the same time, and the wedge iron can be released.

(2) when the oil return valve fails or the oil passage is blocked, and the oil cylinder cannot be reset, if necessary (generally, this method is not necessary, and only D method can be used to solve it), break the quick oil discharge safety valve arranged on the side of the main valve body with a pressure handle to make the hydraulic system discharge oil quickly and unload. (see the general drawing for details)