Maintenance of Nd ━ 1 internal combustion tamping pick

Maintenance and repair

1. Periodic maintenance plan

Content | Maintenance work | Maintenance time |

Air cleaner nut | Is it loose | Every day |

tank | Is the fuel tank cap fastened | |

Throttle line | Is it damaged | |

Air cleaner | Clean or replace | weekly |

Cylinder block | Get rid of the stolen goods | |

a fastening | Whether it is loose and fastened | |

ignition system | Clean the spark plug and check the ignition gap | monthly |

grease | Fill with grease | 20 hours |

Long bolt | Check whether it is loose. If necessary, tighten it with a torque of 75Nm | 80 hours |

Crank gear | Add grease after unpacking | 600 hours |

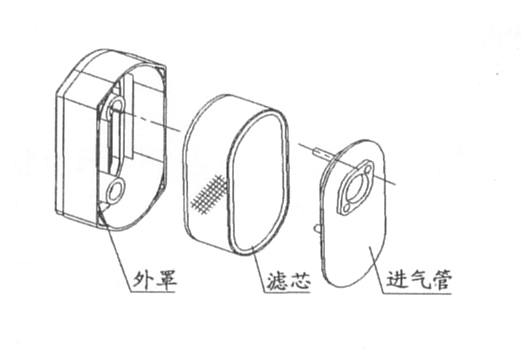

2. Maintenance of air filter

Dirty air filter will prevent air from entering the carburetor, resulting in carburetor failure, intensified wear of gasoline engine and insufficient output power. The air filter should be maintained regularly. If the filter element of the air filter is blocked by dirt, please clean the filter element and the interior of the air filter with gasoline. Put a few drops of engine oil on the cleaned filter element, screw the engine oil dry and install it into the inner cover of the air filter. Note: during cleaning, do not let dirt enter the engine air inlet, otherwise the engine will be damaged.

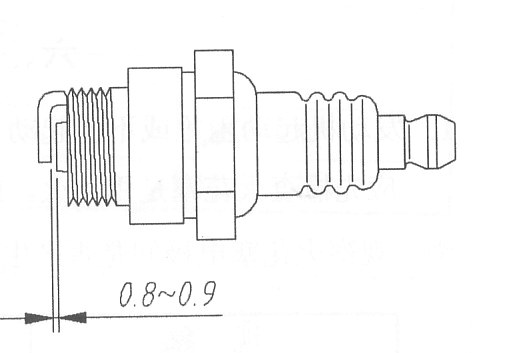

3. Spark plug maintenance

In order to ensure the normal operation of the engine, the gap of the spark plug must be appropriate and free of deposits. The reasonable clearance of spark plug is 0.8 ~ 0.9 mm, which shall be checked frequently. If it is too large or too small, it shall be adjusted. Note: do not use spark plugs with incorrect calorific value.

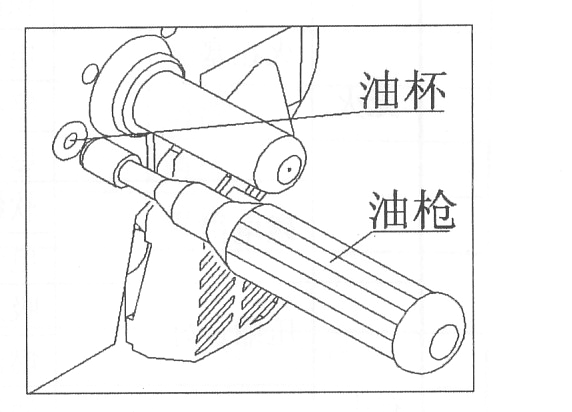

4. Fill with grease

Inject lubricating grease every 20 hours, about 30 ~ 50g.

5. Long term storage

When the machine is not used for a long time, in order to start smoothly next time, the following procedures shall be followed for maintenance:

5.1 drain the fuel in the oil tank and carburetor;

5.2 remove the spark plug, add an appropriate amount of engine oil to the cylinder block from the spark plug hole, gently pull the starter 2 ~ 3 times to make the piston at the top dead center, and then install the spark plug;

5.3 wipe the outer surface of the machine with a soft cloth soaked in engine oil and keep the machine in a ventilated and dry place until next use.

Common faults and troubleshooting

In order to facilitate the user to judge the cause of the fault, common faults and troubleshooting methods are listed below for the operator's reference.

Malfunction | reason | Exclusion method | ||

The gasoline engine cannot be started | No spark plug | Wet electrode | Drying treatment | |

Carbon deposition | eliminate | |||

The electrode gap is too small or too large | adjustment | |||

Spark plug broken | replace | |||

Flameout switch failure | Replace the switch | |||

There is a fire in the spark plug | Good compression | Excessive intake of fuel | Reduce oil supply | |

Poor fuel quality | replace | |||

Carburetor does not supply oil | There is no oil in the oil tank | come on. | ||

The filter screen is blocked | clean | |||

Oil tank vent blocked | clear | |||

Insufficient output power | Good compression | The filter element is blocked | clean | |

Water in fuel | replace | |||

Engine overheating | Shutdown cooling | |||

Carbon deposit on silencer | eliminate | |||

overheated | Carbon deposit on cylinder head | Remove carbon deposits | ||

Poor quality of lubricating oil | Use special engine oil | |||

Flameout during operation | Sudden flameout | Spark plug lead falling off | Firmly connected | |

Piston seizure | Repair or replace | |||

Carbon deposit on spark plug | clean | |||

empty of fuel | come on. | |||

Slow down | Internal blockage of carburetor | clean | ||

Oil tank vent blocked | clean | |||

Tamping pick without impact | Clutch damaged | replace | ||

Damaged or worn gear | replace | |||

The stroke pressure of inner cylinder is too small | replace | |||

Sundries in inner cylinder | replace | |||

Abnormal sound | Lack of grease | Filling | ||

Parts damaged | Repair or replace | |||

Entry of foreign matter | eliminate | |||