Operation of nqg-5.1 internal combustion rail cutter

Structure and working principle

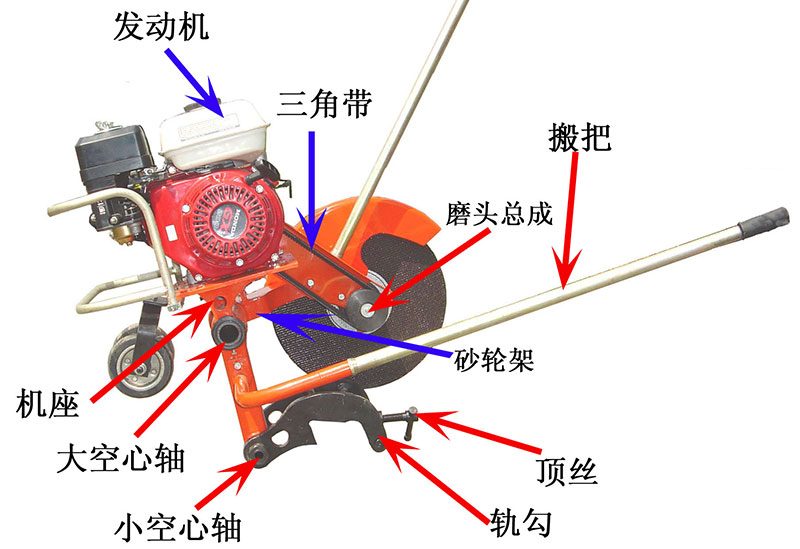

Structure:

1. Main movement: the main shaft (saw blade) rotates driven by the engine and A-type triangular belt.

2. Feed motion: the saw blade feed cutting motion is realized by the swing of the grinding wheel frame relative to the connecting rod frame and the self weight of the rail cutting machine.

3. Transmission principle: the engine is output through the belt pulley and transmitted to the sand shaft through the imported V-belt. The cutting saw blade is installed at the other end of the grinding wheel shaft, and the cutting operation is completed through the rotation of the saw blade.

Use operation

1. First, fill the engine crankcase with four stroke special oil to the position indicated by the dipstick, and try to avoid adding too much oil, so as not to make it difficult for the engine to start. (note at this time: the engine should be placed horizontally. After adding oil and standing for 30 seconds, use the oil dipstick to observe the oil height)

2. Add No. 93 and above pure gasoline into the gasoline tank, and do not fill it up, so as to avoid gasoline overflow during rail sawing and cause fire.

3. Installation of saw blade:

a. Check whether the saw blade is intact, cracked, wet or uneven. It is forbidden to use the saw blade with uneven sides, otherwise it will cause defects such as deflection or clamping, and even accidents.

b. Loosen the fastening bolts of the outer gland of the saw blade, remove the outer pressing plate of the saw blade, install the saw blade, pay attention to the tightness between the saw blade and the inner pressing plate, and then install the outer pressing plate. Pay attention to the oval clamping groove in the outer pressing plate, which must be consistent with the plane on the grinding wheel shaft.

c. Tighten the fastening nut on the outer pressing plate with appropriate torque to prevent excessive torque from crushing the saw blade.

2. Then clamp the rail cutter on the rail, pull the moving rod to make the inner surface (convex surface) of the rail hook close to the top surface and side bottom of the rail, and then lock the bolt.

3. After installing the rail cutter, pull the engine start handle manually to start it. Note that the saw blade should be separated from the rail at this time.

4. Carry out no-load test run: turn the engine flameout switch to the "on" position, open the oil boom switch, and turn the throttle switch to 1 / 3 or 1 / 2. During cold start, close the choke, pull the start pull plate, start the engine, open the choke after the engine runs normally, and then turn the throttle to Z for no-load test run.

5. During the test run, check whether each rotating mechanism is flexible, whether the V-belt, pulley, grinding wheel protective cover and belt cover are intact, and whether the belt tensioning mechanism meets the use requirements. If there is a problem, it can be on the road after handling. It is strictly prohibited to operate machines and tools with defects.

6. Turn off the engine: first turn down the throttle switch, and then turn the flameout switch to the off position.

7. Prepare for the next operation: lift the machines and tools to the rail operation point, hook the rail, rotate the rail hook top wire, do not be too tight, fix the machines and tools, move the machines and tools to align the saw blade with the rail saw rail standard line, tighten the rail hook top wire, and the top wire shall be firmly against the side of the rail top. Note that the working surfaces on both sides of the rail hook must be close to the rail (jaw) at the same time, The rail hook plane must be closely combined with the rail top without gap. Hold the two handrails, swing back and forth, and observe whether the machine hook rail is firm. The rail hook must hook the rail tightly without looseness.

8. Rail cutting operation: Note: no one is allowed to stand in front of the saw blade operator during rail cutting. Start the engine, increase the accelerator to Z, hold the handrail with your left hand to make the saw blade slowly contact the top of the rail, hold the other handrail with your right hand, coordinate the action with both hands and swing back and forth. Because the edge of the saw blade may not be smooth, the saw blade will jump when it just touches the rail surface, so the saw blade should be lighter and the swing range should be smaller when it just touches the rail surface, When the saw blade is sawed into the rail, the swing amplitude is increased, but the left hand does not need to give awesome force. Rail sawing sequence: generally, it starts from the rail head and proceeds in the sequence of rail top - rail waist - inner rail - outer rail. In the jointless track, in order to prevent rail expansion and saw clamping, it can also be carried out in the order of inner rail - rail waist - rail top - outer rail.

9. After cutting: lift the machine with both hands to make the saw blade leave the steel rail, turn down the engine throttle and turn off the engine shutdown switch. After the saw blade stops rotating, loosen the top wire of the rail hook, and the two people cooperate to remove the machine from the steel rail. The rail cutting operation is completed.