Daily maintenance of nqg-5.8 internal combustion rail cutter

Routine maintenance

1. Machine placement

When the machine is not in use, it should be stored in a clean, ventilated and dry place; If it needs to be placed for a long time, drain the gasoline in the fuel tank, start the gasoline engine and run out of gasoline in the carburetor.

2. Regularly check the tightness of bolts (except for bolts used for adjustment) and readjust them if necessary.

3. Check and clean the spark plug.

If the engine power drops, it is difficult to start or the idle speed is unstable, check the spark plug first. The normal operation of spark plugs is affected by the following factors:

·Incorrect carburetor setting;

·Incorrect fuel mixture ratio (excessive oil);

·Dirty air filter.

Check every 50 hours of operation, and replace the spark plug after one month of use. If necessary, shorten the replacement cycle.

(1) Remove the two screws on the plastic cover of the filter, remove the plastic cover of the filter, pull out the rear seat 3 of the spark plug, and remove the spark plug with the attached special wrench for spark plug.

(1) Remove carbon deposits.

(2) Check the electrode gap.

The electrode gap shall be 0.5 ~ 0.6mm, and the spark plug shall be corrected or replaced if necessary.

4. Clean the air filter

The service life of gasoline engine directly depends on the correct maintenance of air filter. Clean the filter once a day. If the working environment is very bad, clean it more often and replace it if necessary.

The pre filter (filter sponge) is made of oil immersed sponge, which mainly filters coarse dust particles. It must be cleaned regularly and soaked with oil to maintain the air filtration effect. Generally, it is cleaned every two times of fuel filling.

The cleaning steps are as follows:

Remove the sponge filter element 1, soak it in warm soapy water, wash it carefully, rinse it and dry it, and then add oil to soak it. Pay attention to that all the filter elements are soaked with engine oil and dry it.

The paper main filter element is located under the sponge filter element and should be cleaned every 1-2 weeks. It can be gently knocked or carefully purged with high-pressure air.

It is difficult to clean the filter element after long-term use. Therefore, the filter element should be replaced regularly. If the air filter is found damaged, replace it immediately.

If the air filter is neglected to be cleaned, carbon will be deposited on the spark plug, resulting in abnormal wear of engine parts.

5. Adjust belt tightness:

Correct adjustment of V-belt tightness is very important for belt service life. Remove the belt protection cover plate and check the belt tightness. If the belt is too loose, loosen the two clamping nuts, screw the adjusting screw with an Allen wrench to adjust the belt tightness, and tighten the two locking nuts after adjustment. Cover the belt guard.

Replace the belt:

Remove the belt guard plate and check the belt. If the belt is seriously worn or tensioned, it must be replaced. Loosen the two clamping nuts, screw the adjusting screw with an Allen wrench, loosen the belt, remove the power support, take out the old belt and install the new belt. Install the belt wheel cover plate and guard plate, install the power bracket, after loading the belt, adjust the belt tightness, then tighten the two clamping nuts.

If the belt is found to be damaged, replace it with a new belt (XPZ belt 9.5) × 825), it is recommended to use the special belt provided by the factory to ensure reliable power transmission.

6. Replace the starting rope and return spring. Replace the starting rope. Unscrew the four screws on the starter and remove the starter assembly. Pull out the starting rope for about 30cm, pull out the starting rope from the opening at the outer edge of the starting wheel, and slowly loosen the starting wheel to its stop position. Loosen the fixing screw in the middle of the starting wheel, remove the starting wheel, and thread a new starting rope into the starting wheel. Replace the starting wheel after winding the starting wheel disc for 3 weeks. Place the starting wheel on the starting spring, ensure that the end of the spring is hooked with the starting wheel, and install the middle fixing screw. Thread the starting rope from the starting wheel rope hole to the starting handle. Tie a rope joint after threading out the starting handle to fix it. Lift the starting rope from the opening at the outer edge of the starting wheel and rotate it clockwise around the starting wheel for 2 weeks. And ensure that the starting wheel can rotate for half a cycle after all the starting ropes are pulled out.

Replace the damaged starting spring

Remove the starting wheel, gently knock the starting wheel (the spring installation side is downward), and take out the starting spring. If the spring pops up during installation, the outer center plate shall be carefully placed in the spring seat. Lubricate the spring with a small amount of oil. Install the starting wheel and tension the starting rope.

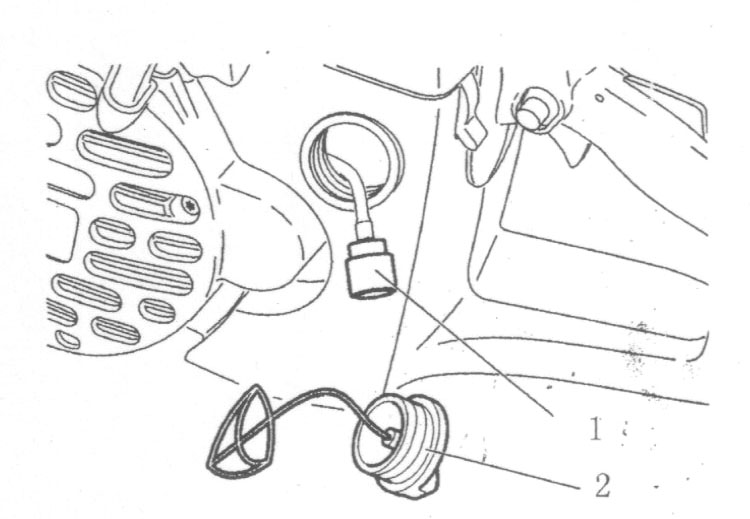

7. Replace the oil suction filter

After the gasoline engine works for a long time, the oil suction filter will be blocked, affecting the power of the gasoline engine.

It is recommended to replace the oil suction filter every three months to ensure the normal operation of the gasoline engine power.

Unscrew the oil tank cover 2, take out the oil suction filter, replace the blocked oil suction filter, put it into the oil tank, and screw on the oil tank cover.

7、 Troubleshooting

Fault phenomenon | Reason | Exclusion method |

Gasoline engine cannot start | Incorrect choke position | Pull it out |

Blocked oil circuit | Item by item inspection | |

Carbon deposit or damage of spark plug | Repair or replace | |

Incorrect spark plug electrode gap | Adjust to 0.5 ~ 0.6mm | |

Excessive proportion of oil in the fuel mixture | Re proportioning fuel paper 1:25 | |

The air filter is seriously blocked | Clean the air filter | |

Serious wear of piston ring or cylinder pulling | Replace or dispose of | |

For some reason, there is too much fuel in the cylinder | Remove the spark plug, turn the throttle to the minimum and start it several times to remove the excess fuel in the engine | |

Unstable speed of gasoline engine | Low ambient temperature | Slowly increase the throttle after idling for a period of time |

Air filter blocked | Clean the air filter or replace it | |

Insufficient cutting force (premise: normal engine) | Belt slack | Proper tensioning |

Clutch slip | Check and replace | |

Grinding head bearing failure | Replace bearing 6202 | |

Poor end face accuracy | Warping deformation of grinding wheel blade | Check and replace |

Deformation of grinding wheel stop or grinding wheel shaft | Check and replace | |

The hinge axis of the connecting frame is not parallel | Check and replace |

Safety code

1. Wear protective glasses, gloves and other protective articles during operation.

2. Before rail cutting, check whether the machine operates normally and whether the grinding wheel is firmly installed.

3. Do not touch the exhaust pipe and cylinder block of gasoline engine to avoid scalding.

4. When refueling the machine, stop the machine and wait for it to cool down. Keep away from the fire source. Smoking is strictly prohibited.

5. The two-stroke gasoline engine uses the mixture of gasoline and engine oil as fuel, and pure gasoline is prohibited.

6. After the gasoline engine is started and before shutdown, it must run at low speed without load for 3 ~ 5 minutes. It is strictly prohibited to run at high speed with large throttle without load and stop suddenly during high-speed operation.

7. In the process of rail cutting, no one is allowed to stand in front and behind the rail cutting, so as to avoid personal injury caused by broken grinding wheel.

8. Turn off the gasoline engine when replacing the grinding wheel.